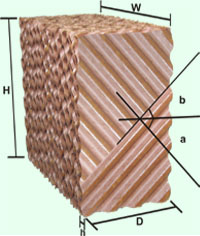

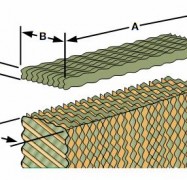

The composition of Evaporative Cooling Pad 7090

Evaporative Cooling Pad 7090, is made of special cellulose paper and highly endosmotic water, with physical flutes having height of wave 7mm. These flutes are united each other to make an angle of cut-off 900 and they look like honeycomb structure. This special design yields larger square face in the same volume space, increases possible contact, rub and collision between air and crumpled face of the pad. Membranous water is taken shape and it covers face of the pad. When air goes through the membranous water, evaporative process into air will happen, simultaneously change temperature and humidity of the air flow. So this process is called the temperature-humidity exchange process.

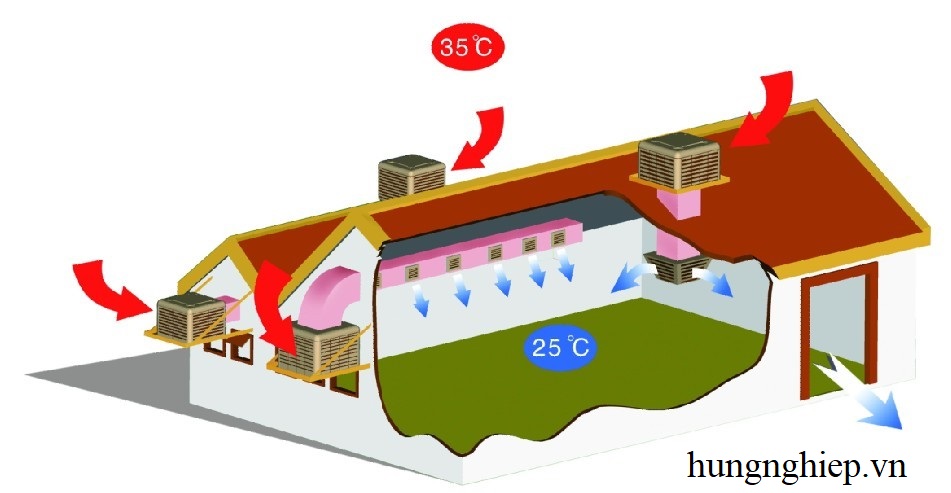

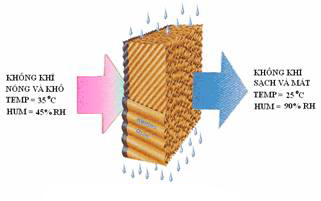

The principle of the pad operation

The temperature-humidity exchange process between water and air: Because water temperature is lower than air temperature exhausted from outside to inside workshop, evaporative water will absorb apart of heat of air and make water hotter, oppositely air becomes cooler and humidity in air increases suitalbly.

Typical applications:

– In the industry such as workshops producing garments, woolen yard, shoes, packing, mechanics, pottery and china, knitting rattan and bamboo, garage,…

– In the services such as restaurant, supermarket, public bar, amusement park,…

– In the farm such as arboretums, places growing flowers, pot plant,…

– In the livestock such as places breeding cattle and poultry,….