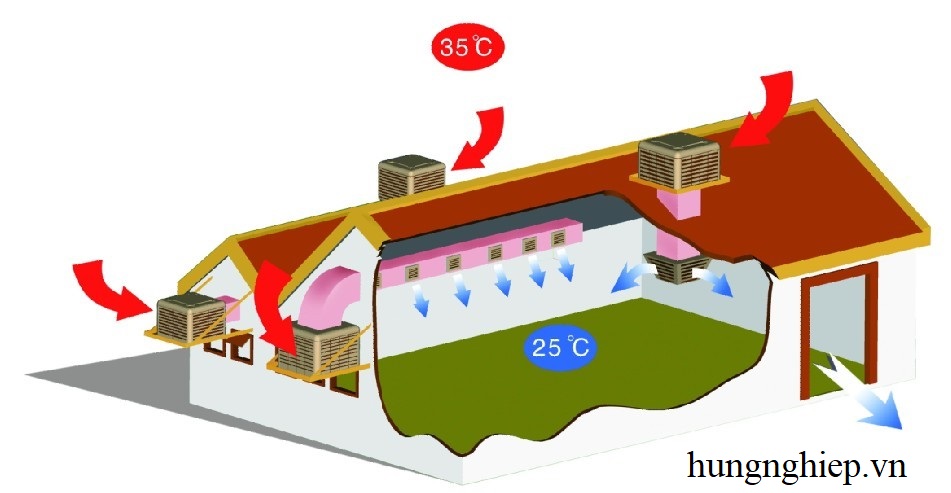

The system of evaporative air coolers making positive pressure is a system blowing fresh and cool air into a workshop and combining the following equipments:

- Evaporative air coolers having large capacity and airflow;

- Pipelines lead fresh and cool air into a workshop;

- Diffuse shutters: Distributing fresh and cool air into a workshop;

- Supports and machine platforms;

- Circulative tanks;

- Water pumps: Supplying water for evaporative air coolers;

- Electric box: Controlling equipments of the system;

- Electric equipments and material.

Evaporative air coolers are installed steady arrangement on all space of a workshop ( making fresh and cool air for all space of the workshop) or only installed to concentrate on parts of the workshop where employees do their works (making fresh and cool air for parts of the workshop). As a result, this system saves investment expenses and electric consumption, but it still makes clear and cool working environment.

When the system of evaporative air coolers operate, water will evaporate into air to decrease air temperature partially, the rest of water return to continue a new circulation, simultaneously, volume of water is also supplied additionally to compensate for partial water evaporating. That is the circulation of water in this system, it helps us to save water and other expenses. Moreover, because volume of water is changed regularly, it helps the system to operate more effective and air flow blowing into the workshop to become cleaner and cooler.

The most salient feature of the system of evaporative air coolers making positive pressure:

- Low expenses of investment and operation: Its investment expenses and electric consumption is correlatively equal 30% and 10% to the system of air conditioners.

- High effect: Air through the coolers will be cleansed and made cool to become abundant oxygen. As a result, the coolers will make ideal environment to increase productivity and guarantee health for employees.