Evaporative cooling system making negative pressure is a system combining the following equipments:

- Exhaust Fans have large capacity and airflow;

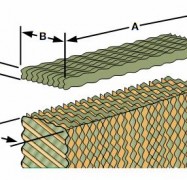

- Frames of evaporative cooling pads including:

- Evaporative cooling pads, called Cooling Pad;

- Water distribution pads;

- Gutters;

- Meshes protecting Cooling Pad from dust, insect (option: yes or no)

- PVC pipes supply water to frames of evaporative cooling pads, PVC pipes take back water from frames of evaporative cooling pads to circulative tanks, and water distribution PVC pipes;

- Water pumps ;

- Circulative tanks;

- Electric box;

- Electric equipments and material;

- PVC sheets adjusting air flow inside a workshop to positions needing to make fresh and cool air (option: yes or no) .

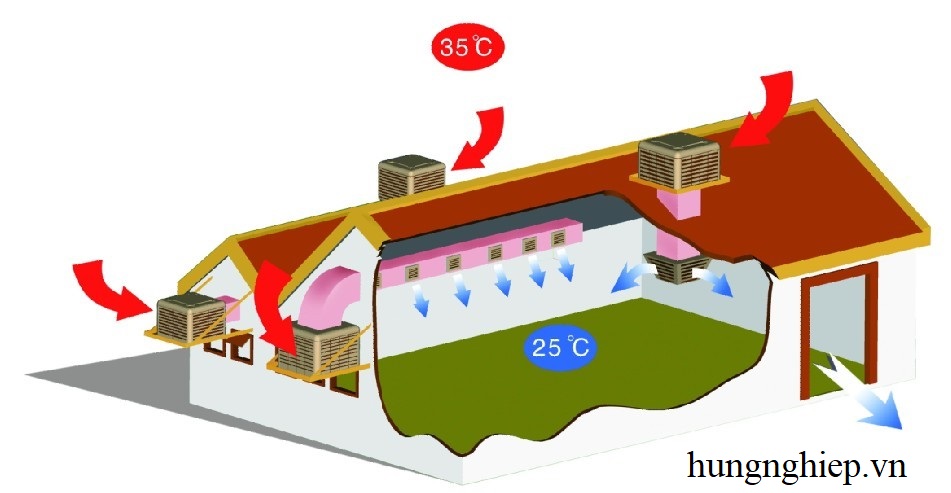

The conditions of a workshop to possibly applying evaporative cooling system making negative pressure include:

– The workshop must be tight;

– In condition the workshop is not tight, it is necessary to consolidate sites not being tight before installing the system such as:surrounding wall, ceiling, roof, heaven gate, slits, windows, doors,…

– When the system operating, the workshop must be closed tight.

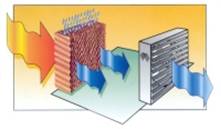

At the opposite gable of the workshop, the system of frames of evaporative cooling pads (including evaporative cooling pads and water distribution pads with a standard size put together and surrounded by stainless steel gutters) is installed. These pads are supplied water regularly by water pump by the way watering regularly on the surface of water distribution pads then wetting all the surface of evaporative cooling pads. After flowing through evaporative cooling pads, water will falls into the gutters and through recovering PVC pipes to return the tank to join a new circulation. Because of the different pressure between inside and outside the workshop, hot and dry air will be exhausted through evaporative cooling pads exchanging temperature with water to become fresh and cool air and suitable humidity. As a result, air temperature inside the workshop is decreased.