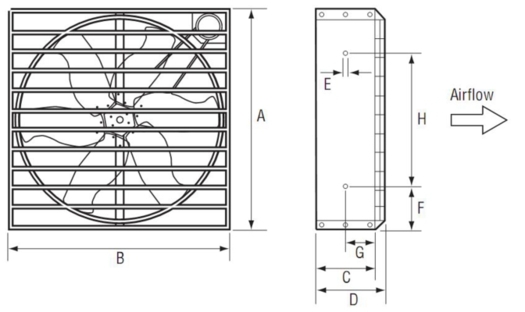

Fan includes its parts such as: one electric motor using three phases, six blades twisted like pea cover, the square fan housing, the propeller central support, the air conveyor, shutter bearings, shutters, couterweight mechanism right and couterweight mechanism left, central pulley, motor pulley, V-belt, pyramidal safety mesh.

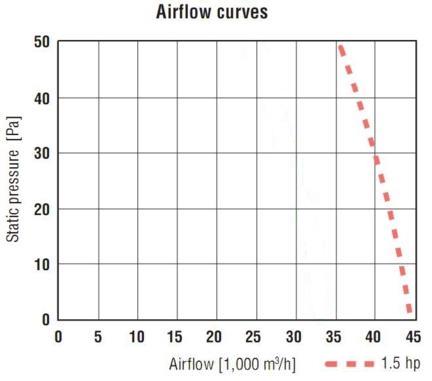

The motor of the fan has 1,1 KW capacity, uses 380V-50Hz 3 phases power. Its axis and ball-bearing is high quality so it gets used to a lot of harsh environment and operates enduringly with over 20 years durability.

The fan has six blades twisted like pea cover. The blades are made of stainless steel and pressed by machines with high technology so they are able to sustain high pressure, erosion and be self-cleaning. The fan is statically and dynamic balanced for the highest efficiency, low noise and low vibration.

The propeller is attached to a central pulley and motor by a large v-belt being able to adjust the tension. The axle-bearing is embeded a double ball bearing protected agaisnt water. The belt transmission ensures low propeller rpm, which ensures high efficiency, low enery consumption as well as low noise.

The square fan housing and air conveyor is made of galvanised steel with 1,2mm thick and strengthened by making ribs. Because of these, the fan becomes highly solid and sustains huge pressure.

Shutter side is made up shutter blades united them with two couterweight mechanisms. These couterweight mechanisms will help shutter side automatically to open and close synchronically and quietly. The shutter blade is made of galvanised steel, which is stronger than aluminium, aluminium alloy and plastic, and strengthened by making ribs to sustain huge pressure and make firm and tight structure.

Shutter side is opened automatically by the air flow when the fan is working and closed tightly automatically to prevent any air leakage, rain, sunshine, dust from the fan and guarantee the safety of workshop when it is not working. The shutter does not have to be cleaned regularly as being self-cleaning and dust does not affect its opening and closing movement. All turning hinges of shutters are made of acetalic plastic with UV protection.

When the fan starts to work, shutter side is is opened automatically by the air flow with aperture reaching 900 maximum. This aperture is maintained by couterweight mechanisms. Because of only needing a first air pressure to open shutters, capacity is wasted little, air flow is high and very higher than the patented centrifugal system which always wastes a partial capacity to maintain the opening of shutters during the fan is working. When the fan is not working, shutter side is closed tightly automatically by couterweight mechanisms effected by the difference of pressure between inside and outside of the fan.

Pyramidal safety mesh is installed at the rear opposite to shutter side to guarantee the safety when the fan is working.

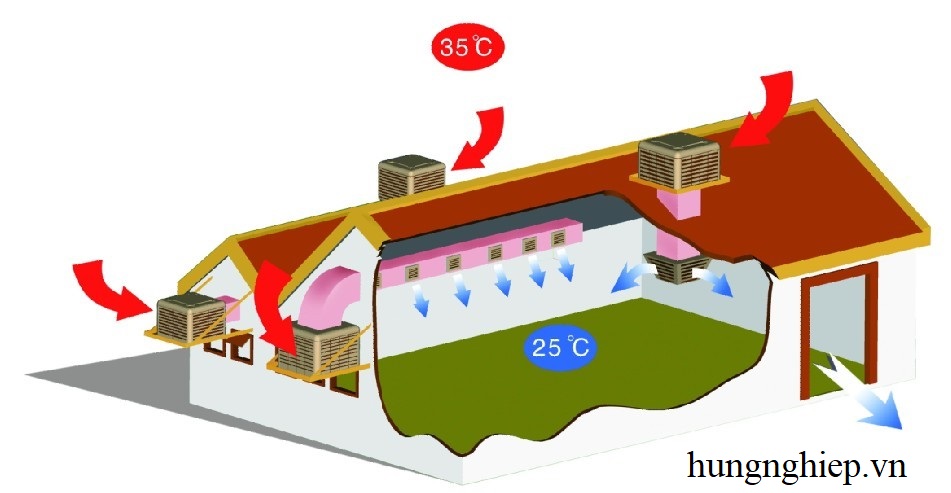

When Exhaust Fan HF1380 is combined to the system including cooling pads and inox gutter, they will make the evaporative cooling system making fresh, cool and more oxygenic air, the movement of air and the ideal working condition in workshop.

Main applications:

– Ventilating, cleaning surfaces by suction, discharging heat, making fresh and cool air for workshops producing mechanics, garments, woolen yard, shoes, packing,…

– Ventilating, making fresh and cool air for farms breeding cattle and poultry,…

– Ventilating, making fresh and cool air for glasshouses planting fresh vegetable, flowers, pot plants, seedlings,….